Ceramsite Proppant

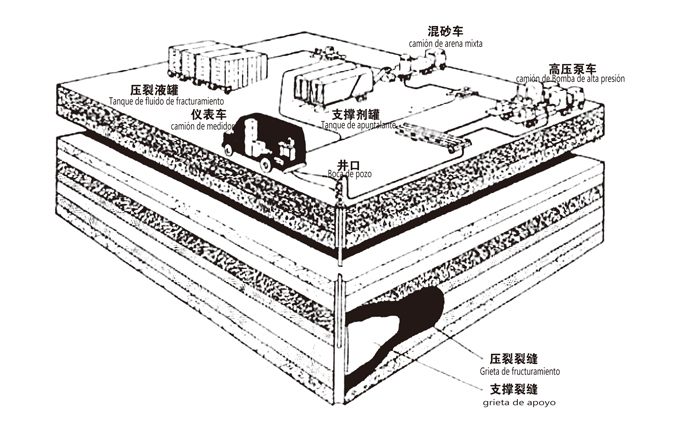

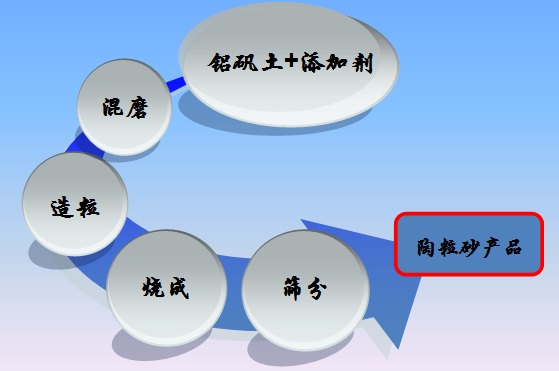

Ceramic sand also named fracturing proppant, it’s a kind of ceramic particles product which is widely used as underground propping for oil field and gas filed. The proppant can increase the production of oil, natural gas, coal-bed methane and shale gas. It’s a kind of environment -friendly product. This proppant is made by high quality bauxite which can take place of low strength propping products like natural quartz sand, glass grain, metal grain & etc.