1.Application of Magnesium

(1)Producing reducing agent of refractory metal. Magnesium can used to produce reducing agent like Titanium, Zirconium, Hafnium, Beryllium, Boron etc. Also the annual usage of agent to producing metallic Titanium have increased year by year.

(2)The adding element for Aluminum Alloy.

(3)The nodulizing agent for nodular cast iron.

(4)Desulfurizing agent for steel desulfuration.

(5)High storage capacity material. Magnesium will transfer to magnesium hydride under the condition of normal pressure, 523℃ mixing with hydrogen. And under the condition of low pressure and higher temperature will produce hydrogen again, so magnesium is the perfect material for hydrogen storage.

(6)Fireworks. Magnesium have been widely used for producing fireworks, signal shell, star shell, incendiary shell.

2. Application of Magnesium Alloy

The Magnesium Alloy have mainly applicable for Aerospace industry, Automobile industry, Motorcycle and Bicycle industry, Shipping industry, National Defence industry, 3C(Computer, Consumer Electronic product, Communication), Medical Industry, sacrificial anode industry, Antiseptic industry and other fields.

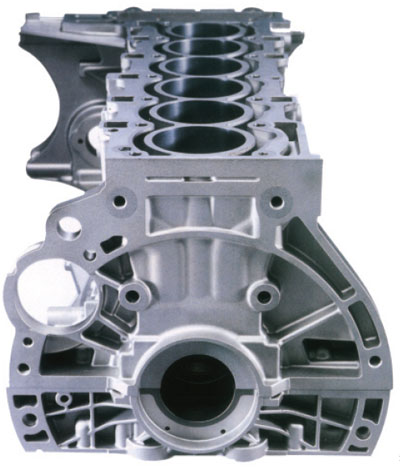

The advantages of Magnesium Alloy automobile parts can be concluded to: Small density to reduce weight of whole vehicle, reducing fuel consumption indirectly; The specific strength of Magnesium Alloy is higher than Aluminum Alloy and Steel, specific stiffness is close to Aluminum Alloy and Steel, that will be bear a certain load; Magnesium Alloy have perfect castability and dimensional stability, which will be easy to processing with low rejection rate; Magnesium Alloy have perfect damping factor, vibration reducing is higher than Aluminum Alloy and Casting Steel, can be reducing noise when used for shell and reducing vibration when used for seat and rim, which will enhance the safety and comfort of the vehicle. Magnesium Alloy Pressured Casting Parts have showing long-term growth on the field of vehicle application. In the past ten years, it’s growing speed have exceed 15%.

The magnesium alloy can satisfy with the requirement of lightweight material noise absorption, damping and radiation protection in aerospace and other high-tech area, which can great improve gas dynamics performance of the aircraft and reduce the structure weight. From 1940s, the magnesium alloy was first widely used in aerospace department. The B-36 heavy bombers used 4086kg magnesium alloy plate for each one from abroad. The wing of Lockheed F-80 jet fighter used magnesium plate, and then the structure parts quantity reduced from 47758 to 16050. The Chinese fighter plane, bomber, helicopter, transport plane, civil aircraft, aircraft radar, surface-to-air missile, carrier rocket, artificial satellite, airship were all used magnesium alloy component. Each model of the plane was able to choose the magnesium alloy components with the maximum quantity of 300 to 400. The weight of one part is nearly 300 kg. The maximum size of one component is more than two meters.

In order to increase the structure hardness, reduce equipment weight and increase the weapon accuracy which should use the magnesium alloy plate in military industry.

In recently 20 years, the global automotive output has sustainable growth, the AAGR is 2.5%. The development of automotive industry is an important one kind of development mark for a country, but the metal material is the important foundation for the development of automotive industry. Because of the requirement of Energy Conservation and Environmental Protection, the automotive designer tries to reduce its weight to reach the reduction of petrol consumption and exhaust gas emission. As the lightest structure material, the magnesium alloy can satisfied the increasingly stringent requirement for the energy saving exhaust gas emission, which can produce new model automotive with less weight, low petrol consumption and environment protection. The advantage of magnesium alloy automotive parts was concluded as follows:

The lower density was able to reduce the entire weight, then reduce the fuel oil consumption indirectly.

The hardness of magnesium is higher than aluminum alloy and steel, which rigidity was similar with aluminum alloy and steel to bear a certain load.

The magnesium has well castability and dimension stability, which processing was easy and low waste.

The magnesium has well damping factor and the vibration quantity was larger than aluminum alloy and steel, the noise can be reduced when it used for case, and the vibration can be reduced when it used seat and wheels, then the safety and comfort can be increased.

At present, the magnesium alloy die casting products were widely used in Instrument, car seat frame, direction control system components, engine hood, gearbox, intake manifold, wheel hub, engine and security components.