Lime Slaking Plant

Slaker modelZKX-3~ZKX-20

Seperator modelNHX-500~NHX-800

Slaking temp./ ℃80~100

Feeding size(mm)≤40

Introduction

ZK Corp provide complete solution for active lime project, energy saving rotary lime kiln process, vertical lime kiln process, lime grinding plant, lime slaking plant, etc

Lime can be divided into two types: ordinary lime and active lime. The former is mostly fired in earth kilns and ordinary shaft kilns, and its activity is generally within 200ml, which is mainly used for construction and road repair; the latter is mainly composed of mechanical shaft kilns and rotary kilns. After calcination, the activity can reach 300~420ml. Limes calcined in rotary kilns are of better quality, and they are mainly used in industries such as steel smelting, chemical industry and power plant desulfurization.

Our Advantage

1. The equipment occupies small area, the output capacity for unit volume is high, the materials mostly are full of the tank of the slaking machine, the utilization rate is more than 92%.

2. This system has the good operation environment, it realizes the mechanized production. There is slag-removing machine after the slaking machine, which can separate 95% of slags in lime.

3. This system has high mechanization, and easy for operation and controlling. The slaking and slag-removing can completely realize the mechanization, so, during the normal production, no need workers for operation, with low labor intensity.

4. This system adopts negative air and pulse technology, and uses Integrated computer to control production. The slaking system includes primary slaking, secondary slaking, third slaking to make the lime slaked uniformly. The slaking rate is ≥ 98%.

5. This system adopts close-type recycling air classifying method which can make the final Ca(OH)2 products’ fineness reach to 100-800 mesh. The final products can be divided into different

grades.

6. The capacity varies from 3-20tph.

7. The fineness of final products varies from 100-800 mesh with purity ≥ 97% and moisture ≤ 1%.

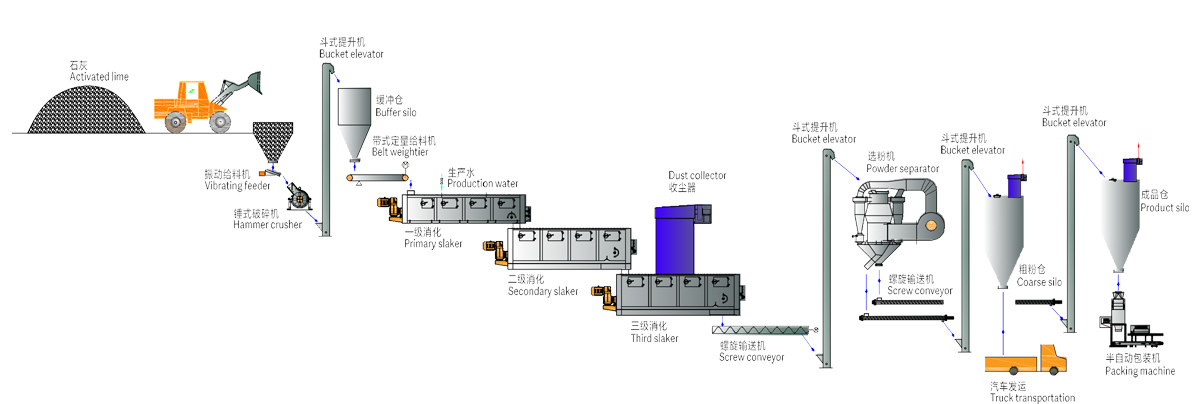

Production Technology

The qualified lumpy lime is firstly crushed into the sizes about 40mm by the Jaw crusher. Then the crushed sizes will be sent into the buffer silo by bucket elevator. Under the bottom of the storage silo, there is steady flow conveyor quantitatively weighing system. After weighing, the lime is sent into the primary slaking machine, and then enter into the secondary and / or third slaking machine, to make the lime completely slaked to get the quality primary products. The slaking rate can reach to 98%. The slaked lime is sent into the powder classifier by the semi- products screw conveyor for separation of the impurities and fine powder. After classifying, the quality final products is sent into the final storage silo by final-products screw conveyor and bucket elevator for packing or bulk loading. Hydrated lime is an ideal product for environmental protection in coatings, power plant desulfurization, water purification and mediation for water PH value.

Configuration

| capacity (t/h) | 3 | 6 | 8 | 10 | 12 | 15 | 20 |

| Main equipment | Main supporting equipment model and technical & economic iindex | ||||||

| Slaker model | ZKX-3 | ZKX-6 | ZKX-8 | ZKX-10 | ZKX-12 | ZKX-15 | ZKX-20 |

| Power/kW | |||||||

| 7.5+7.5 | 11+11 | 7.5*2+11 | 7.5*2+11*2 | 7.5*2+11*2 | 11*2+11*2+11*2 | 11*2+11*2+11*2 | |

| Stages of slaker | 1 | 2 | 2 | 3 | 3 | 3 | 3 |

| Slaking time/min | |||||||

| 50 | 50 | 55 | 55 | 55 | 60 | 45 | |

| Dedusting air volume/m³/h | |||||||

| 4500 | 9000 | 12000 | 15000 | 18000 | 22500 | 30000 | |

| Dedusting negative pressure/Pa | |||||||

| 500 | 1000 | 1000 | 1500 | 1500 | 1500 | 1500 | |

| Bag filter model | ZM80 | PPC32-4 | PPC32-6 | PPC64-4 | PPC64-5 | PPC64-6 | PPC64-7 |

| I.D. Fan Power /kW | 7.5 | 15 | 15 | 30 | 45 | 75 | 75 |

| Separator model | NHX-500 | NHX-600 | NHX-600 | NHX-700 | NHX-700 | NHX-800 | NHX-800 |

| Separator power/kW | |||||||

| 7.5 | 11 | 11 | 15 | 15 | 18.5 | 18.5 | |

Related Project Case

200tpd Quick Lime Plant in Iran

Shanxi Jiangqiang Activity Lime Co., Ltd...

150 tons/day Lime Project in Uzbekistan

100TPD Shaft kiln For Quicklime Plant in...

50TPD Quick Lime Plant Project in Iran

Africa Congo 50,000 t/a Active Lime...

The whole-set equipment of Anyang lime...

Fugu Yihe Magnesium Co., Ltd lime...

Ningxia Baota Union Active Lime...