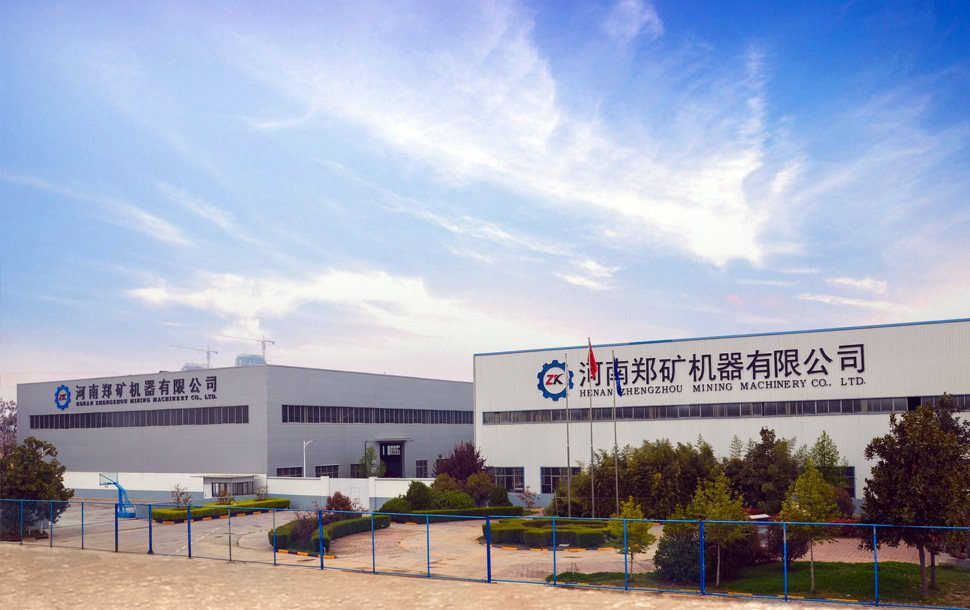

Henan Zhengzhou Mining Machinery Co., Ltd (hereinafter referred to as “Henan ZK Corp”)., founded in 1956, is a designated production unit of building materials and mining machinery designated by the National Ministry of Machinery Industry and Henan Provincial Department of Machinery and Electronics Industry. After more than 60 years of development, our company has gradually developed from a single mechanical equipment manufacturing enterprise into a comprehensive company with strong ability of the whole system researching and designing on process technology and equipment manufacturing in the fields of building materials, mining, metallurgy, environmental protection etc.