Introduction

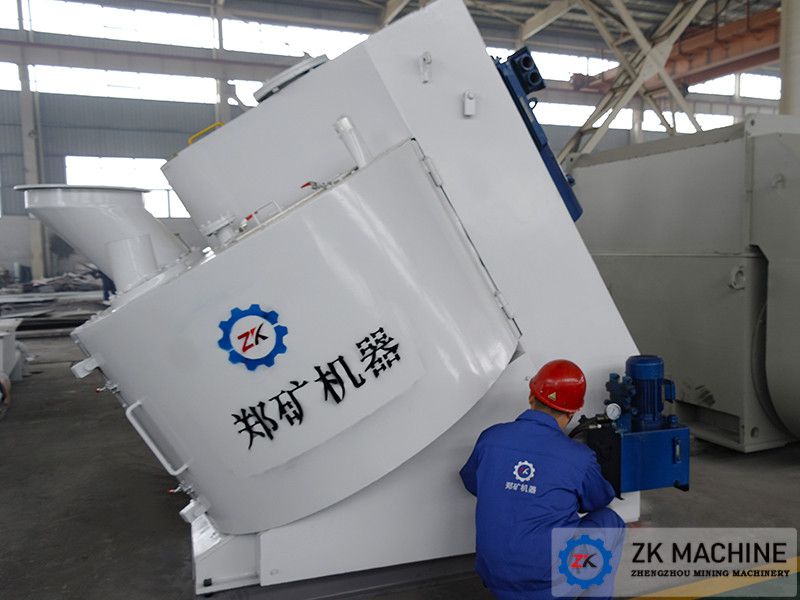

ZKZL Series Clean Type Powerful Granultor produced by Henan Zhengzhou Mining Machinery Co., Ltd is developedon the basis of absorbing and learning from advanced technology abroad, combining with the current production status of petroleum fracturing proppant in China.

Application:

It is mainly used for production of petroleum fracturing proppant (ceramiste sand), and also be applied for granulation of powder, granule, small pieces material such as coal powder, limestone, coal gangue, clay and etc.

Working Principle:

ZKZL Series Clean Type Powerful Granultor is mainly composed of drum, rotor assembly, scrapper device, discharging device and frame. The working principle is to utilize the reverse movement between low speed clockwise rotating drum and high speed counterclockwise rotating rotor to stir material at high speed. There are separate scrapers at the bottom part and wall of the drum. The interaction between drum wall cleaning by scraper and the movement with inclined rotating drum forms a special flow field to change the movement direction of material. Powdery material is "rubbed" to cores during high-speed movement and then and then granulated into a ball.

Features

1. The whole process of granulation is inside the fully enclosed drum, and the drum interior is at slightly negative pressure state. It is without dust pollution, clean and environmental friendly.

2. Feed - mixing - nucleation - granulators - shaping,the whole process is controlled by computer through PLC. It is easy operation and high degree of automation;

3. After abrasion treatment, the rotor surface had made precise balancing to ensure movement stability, reliability and wear resistance under high rotational speed. So that the machine can work stable and reliable;

4. The scraper surface has had appropriate wear treatment. The bottom and the inside of the drum is equipped with wear-resistant liner, therefore, the entire drum parts have a long service life;

5. The drum discharge part is fully hydraulic drive. It has the advantages of high automation and reliable drum sealing.

Technical Parameter

|

Model |

Max loading amount |

Power(kW) |

Total weight(t) |

|---|

|

Weight(kg) |

Volume(L) |

|---|

|

ZKZL-15 |

400 |

500 |

90 |

5 |

|

ZKZL-16 |

500 |

600 |

110 |

6.5 |

|

ZKZL-19 |

800 |

1000 |

132 |

10 |

|

ZKZL-24 |

1300 |

1500 |

185 |

13.5 |

Project Cases