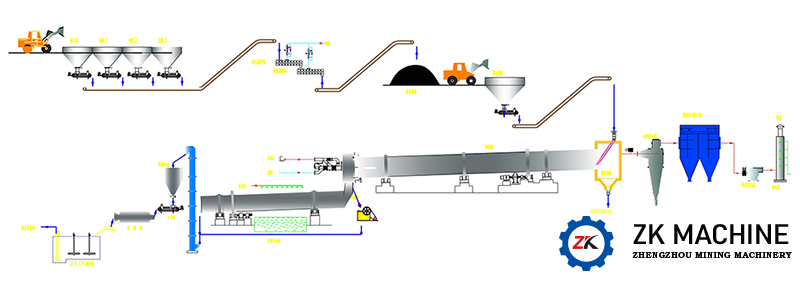

LITHIUM PRODUCTION LINE

Processing capacity: 1000-20000 t/a

Raw material: Spodumene, lepidolite, lithium ore

Rotary kiln diameter: 1.5-4.5m.

The production line for roasting and acidizing lithium ore with lepidolite, spodumene and other raw materials configured by our company has excellent product performance, stable production condition and easy operation, which has received positive recognition from users. The kiln adopts wireless temperature monitoring system and remote intelligent variable speed kiln condition control system, which is convenient for production personnel to adjust kiln condition in real time. The raw material crystal conversion rate is high, the acidification is complete, and the lithium leaching rate and lithium recovery rate are 15% higher than the traditional process.