Introduction

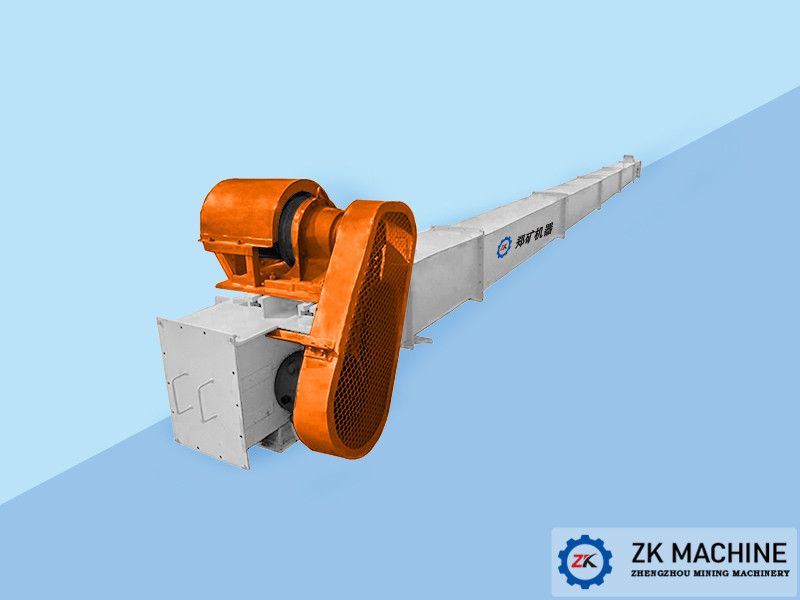

BL series apron conveyor is driving by cycle running chain, that can transport all kinds of bulk materials along horizontal or inclined (inclination angle is less than 25 °) direction. Since the carrying part and running parts are made by metal, thus compared with other continuous conveying machinery, apron conveyor can transport material with bigger bulk density & size, and material with sharp edges with strong abrasion, especially suitable for conveying high temperature( 600 ~ 700 ℃ )material. Therefore, apron conveyor is wildly used in mining, building materials, metallurgy, coal, chemical and other industries for transporting sharp, burning, corrosive material.

Application of Apron Conveyor:

Transporting high temperature material for cement, lime, clinker, mining industry.

Features

1. Apron bucket made by wear-resistant steel plate with high precision, the cumulative error is small, running accurate, stable and reliable;

2. Adaptable, can transport material with bigger size & sharp edges & high temperature. In the transportation process the conveyor will complete material cooling and cleaning at the same time.

3. With chain transmission, apron conveyor has advantage of high intensity, high efficiency, reliable operation, heavy load, suite for long-distance transportation;

4. The chain has heavy load, high strength and high impact resistance because of heat treatment; chain plate joint sleeve use alloy steel carburizing with high abrasion resistance;

Technical Parameter

|

Type |

Feeding Trough Width (mm) |

Speed (m/s) |

Side Height (mm) |

Chain Pitch (mm) |

Max Capacity (m3/h) |

|---|

|

Light |

400 |

0.05-1.60 |

160-250 |

200 |

450 |

|

500 |

160-315 |

700 |

|

630 |

200-400 |

1150 |

|

800 |

250-500 |

250 |

1850 |

|

Medium |

800 |

0.05-1.00 |

160-400 |

250 |

900 |

|

1000 |

200-500 |

1400 |

|

1200 |

250-500 |

315 |

1750 |

Project Cases