Introduction

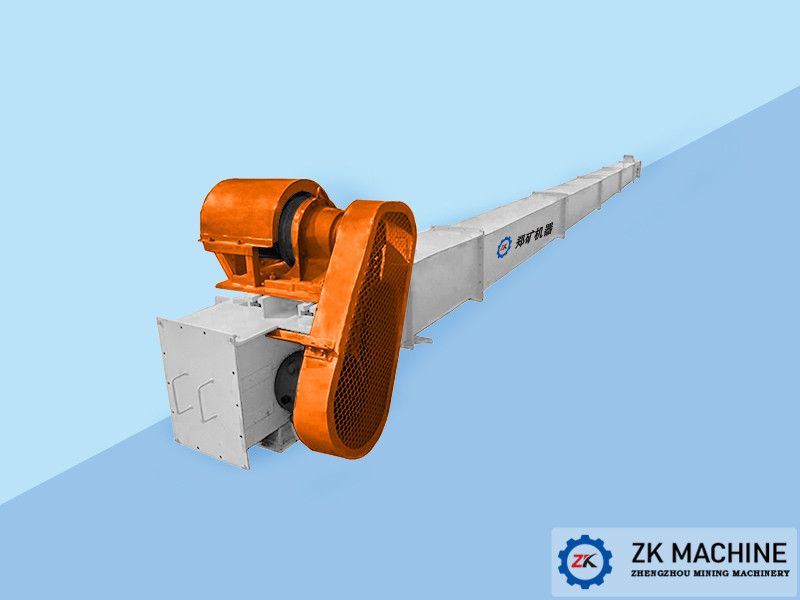

DTII fixed belt conveyor is the upgrade product from TD75. It has stronger adaptability, can be widely used in metallurgy, mining, coal, chemical industry for bulk materials and packaged product conveying. Single equipment can be used, multiple or composition with other conveyors for horizontal or inclined conveying system. The operation temperature of belt conveyor is from -25℃~40℃,and request temperature of conveyed materials not exceed 60℃;The heat resistance rubber belt can convey the high temperature materials that below 120℃,the belt conveyor is not suitable for convey higher temperature materials. The oil-resistance, acid resistance rubber belt are used to convey acid, alkaline, oil materials and some materials with organic solvent.

Application of Belt Conveyor:

Power, Metallurgy, Construction, Light industry, Grain, Mining industry and so on.

Features

1. The range of conveyed materials is widely. Wet, dry, powder, block materials and packaged product are can be used belt conveyor;

2. The capacity is large, the convey distance is length;

3. Multiple spot feeding and discharge can be realized in one belt conveyor;

4. Continue operation , running steady and small noise;

5. Simple structure, work reliable , easy operation ,installation and maintenance.

Technical Parameter

| Specification | Belt width(mm) | Sidewall height(mm) | Diaphragm plate

Spacing(mm) | Belt Speed(m/s) | Inclinationβ(°) | Capacity(m3/h) | Max Material Size(mm) | Power(kW) |

|---|

| DJ500 | 500 | 80 | 126~252 | 0.8~2.0 | 30~90 | 84 | 100 | 1.5~18.5 |

| 100 | 112 |

| 120 | 126~378 | 138 |

| DJ650 | 650 | 80 | 126~252 | 0.8~2.0 | 156 | 140 | 1.5~22 |

| 100 | 172 |

| 120 | 126~378 | 186 |

| DJ800 | 800 | 80 | 126~252 | 0.8~2.0 | 186 | 180 | 2.2~45 |

| 100 | 318 |

| 120 | 126~378 | 360 |

Project Cases