Introduction

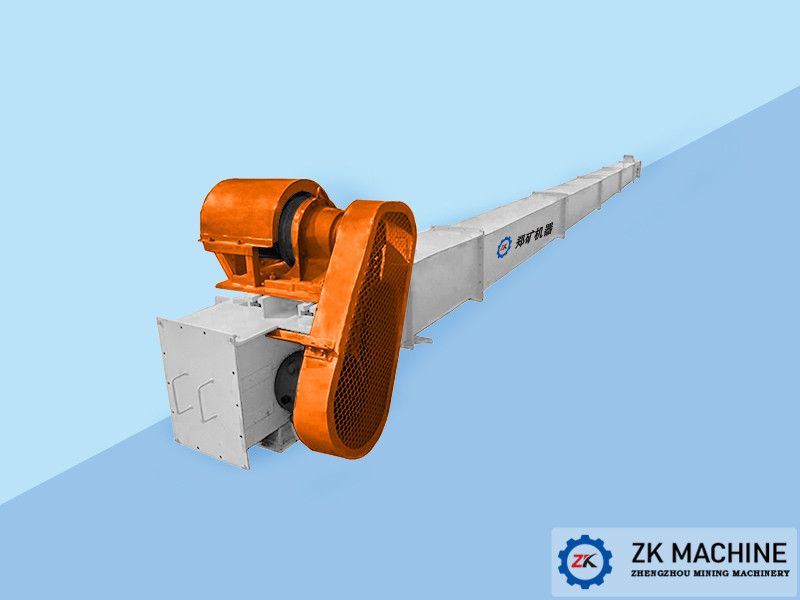

DJ Inclined belt conveyor uses corrugated sidewall belt instead of normal belt. Its structure and working principle is same with belt conveyor, and most of its components can be used by normal belt conveyor. DJ Large angle belt conveyor can continuously convey all kinds of bulk material with bulk density 0.5~2.5t/m³at environment temperature -25℃~40℃. Maximum angle of inclination is 90°, and maximum size of the material should ≤180mm. The corrugated sidewall belt need to be replaced by belt made of special material when conveying special material. According to the flow chart, it can work alone or combine with other conveyors to make an inclined conveying system, to achieve long distance and long span material conveying. Nowadays, our products can meet the purposes and requirements of different users, and establish a good reputation in cooperation clients.

Application of Inclined Belt Conveyor :

Usually used for conveying powdery, granular and other bulk materials in Electric power, metallurgy, building materials, light industry, food, mining and other industries.

Features

1. Reliable operation. Its reliability is almost same with normal belt conveyor.

2. With corrugated sidewall belt and diaphragm plate, its maximum angle of inclination can reach 90 degree, which will save a lot of floor space, equipment investment and construction cost. So, DJ Large angle belt conveyor is the most ideal equipment for large angle and vertical conveying.

3. Stable operation, low noise. The noise can be ignored since

4. By improving the structure of the head, we decrease the tension from 800N/mm to 400N/mm, which will extend the belt working life and reduce the maintenance costs for customer.

5. Large capacity. With corrugated sidewall belt, its capacity is larger than normal belt conveyor at same inclination.

Technical Parameter

| Specification | Belt width(mm) | Sidewall height(mm) | Diaphragm plate | Belt Speed(m/s) | Inclinationβ(°) | Capacity(m3/h) | Max Material Size(mm) | Power(kW) |

|---|

| DJ500 | 500 | 80 | 126~252 | 0.8~2.0 | 30~90 | 84 | 100 | 1.5~18.5 |

| 100 | 112 |

| 120 | 126~378 | 138 |

| DJ650 | 650 | 80 | 126~252 | 0.8~2.0 | 156 | 140 | 1.5~22 |

| 100 | 172 |

| 120 | 126~378 | 186 |

| DJ800 | 800 | 80 | 126~252 | 0.8~2.0 | 186 | 180 | 2.2~45 |

| 100 | 318 |

| 120 | 126~378 | 360 |

Project Cases