Introduction

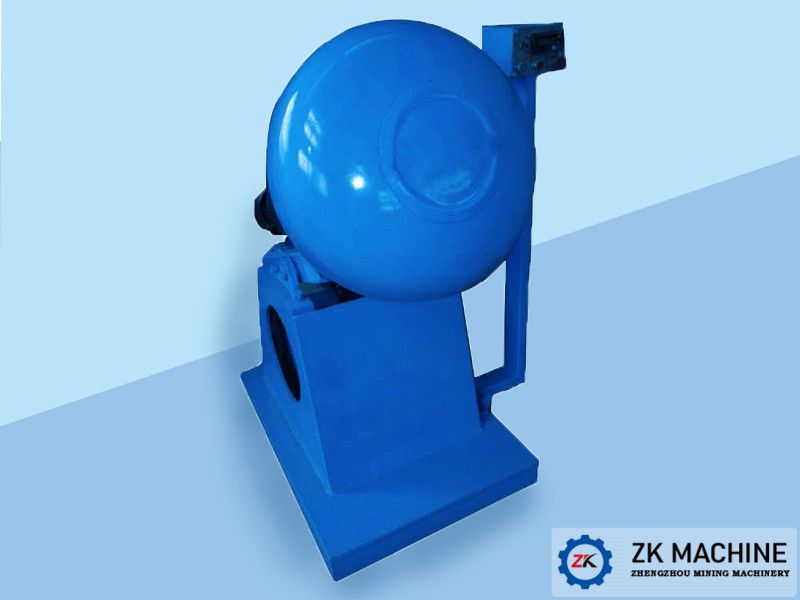

This briquetter is mainly designed to press the mixed material of calcined, dolomite, ferrosilicon and fluorite into briquettes for the Mg0 reduction in Pigeon Process. It can also be used for the brigquetting powders of aluminum, AI203, limestone and clay to control dust emission or to make it more convenient for transportation.

The Briquetter can be used for pressing iron, iron oxide, iron, coal, coke, aluminum powder, gypsum, tailings, toner, charcoal powder, slag, sludge, kaolin, activated carbon, coke powder and other powder, waste residue. It is widely used in power plants, metallurgy, refractory, chemical, energy, transportation, heating and other industries. The Briquette machine production is after the molding material, which is energy saving and environmental protection, convenient transportation, improving the utilization rate of waste. It has good economic benefit and social benefit.

Features

This series of briquetter has the advantages of reliable equipment operation, stable pellet quality, large production capacity, simple maintenance operation, and small dust pollution during the production process.

Technical Parameter

Model

| Roller dia.(mm)

| NO. of pit(个)

| Roller width(mm)

| Capacity(kg/h)

| Main motor power(kW)

|

|---|

LYQ0.5 | Φ299 | 108 | 180 | 500 | 18.5 |

LYQ1.0 | Φ367 | 200 | 183 | 1000 | 37 |

LYQ1.5 | Φ367 | 200 | 183 | 1500 | 45 |

LYQ2.0 | Φ399.5 | 240 | 252 | 2000 | 45 |

LYQ3.0 | Φ522 | 300 | 196 | 3000 | 55 |

LYQ5.0 | Φ738 | 504 | 210 | 5000 | 75 |

Φ700 | 560 | 225 |

LYQ6.0 | Φ738 | 504 | 220 | 6000 | 90 |

LYQ8.0 | Φ758 | 616 | 225 | 8000 | 110 |

LYQ10 | Φ858 | 1000 | 300 | 10000 | 132 |

Project Cases