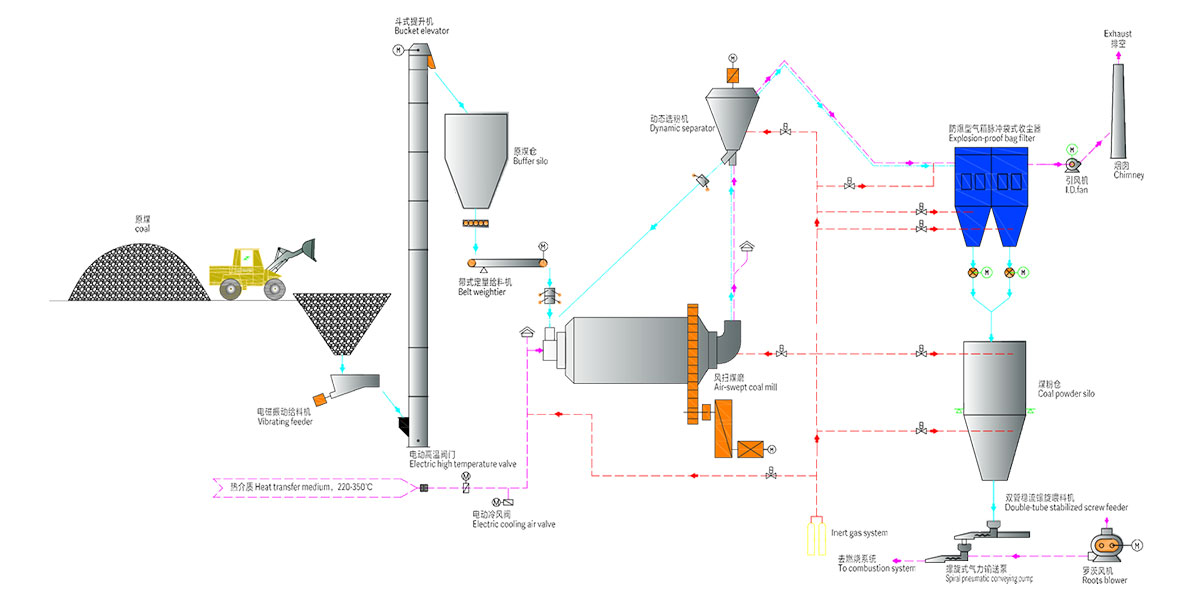

PULVERIZED COAL PREPARATION PRODUCTION LINE

Capacity: 50,000-300,000 t/a

Main equipment: air swept mill, dynamic powder separator, explosion-proof dust collector

Raw Material:Lumpy Coal< 25mm

From raw material storage and transportation, pre-drying, grinding, powder selection, cooling to finished product storage and transportation system, environmental dust collection system, process design of electrical automation control system, plant planning, equipment supply, equipment installation and commissioning, after-sales training and a series of technical services