- GGBS Production Line

- Solid Wate Incineration System

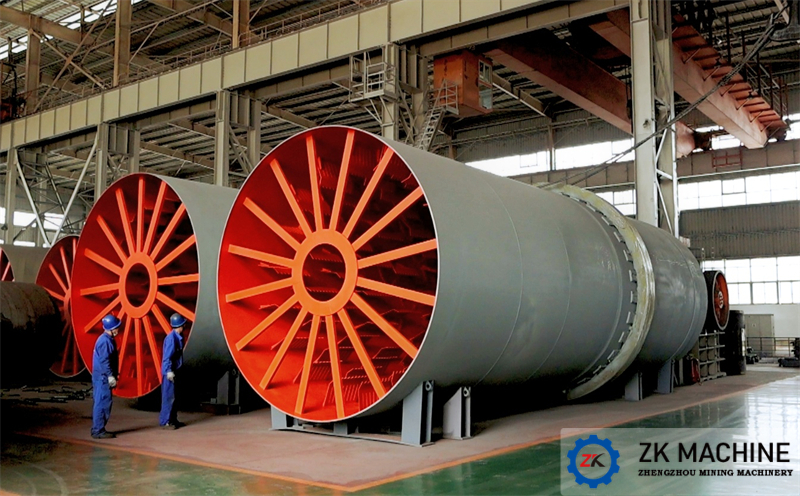

- Pulverized Coal Preparation System

- Molecular Sieve Production Line

- Flue Gas Purification System

- FGD System

- Waste-Co-Processed New Building Materials

- Soil Remediation System

- Gypsum Powder Production Line

- Aluminum Ash Production Line

- Suspension Rosting Furnace Pilot Line