ZK energy-saving ball mill is your new choice

Henan Zhengzhou Mining Machinery Co., Ltd is an integrated modern enterprise with scientific research, design, development, manufacturing, sales, installation, commissioning and training services. Our research and design team develop our own energy-saving ball mill on the basis of absorption and the introduction of foreign is advanced technology. This energy-saving ball mill adopts the double row self-aligning roller bearing instead of the sliding bearing in the drive part. The friction is changed from sliding type to rolling type, which realizes the reduction of resistance and friction to save energy consumption and cost and extend service life of energy-saving ball mill.

ZK energy-saving ball mill

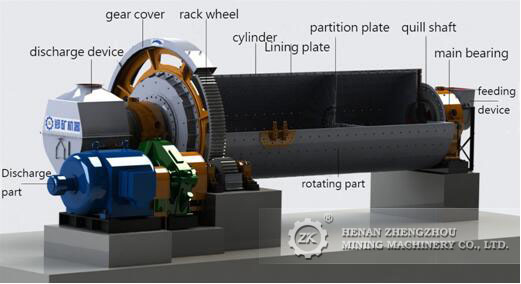

ZK energy-saving ball mill mainly consists of rotary part, main bearing, feeding device, discharge device, transmission device, etc.

Structure diagram of energy-saving ball mill

The sliding bearings of both cylinder ends in the cylinder of energy-saving ball mill are replaced by rolling bearings to save consumption. The power of its matching motor can decrease 18-25%. At the same time, it saves 70% lubricating oil and 90% cooling water. In comprehensive energy saving can be 20% or above. The cylinder is the main component with smaller diameter and longer length. The cylinder is driven by the transmission device with slow movement. When the materials are brought to the inner mill by feeding device, under the friction and centrifugal force which is produced by cylinder rotating movement, the materials and grinding medium are elevated to a certain height, and then they are dispersed like a curtain. The materials are grinded by the grinding medium. The continuous feeding makes the materials move from the feeding end to discharge end. The fine materials are discharged from discharge end. For wet grinding, the materials are discharged by water; for dry grinding, the materials are discharged directly.