Application Scope and Selection Principles of Buried Scraper Conveyor

1. Conveying principles and characteristics

The buried scraper conveyor is a continuous conveying equipment for conveying bulk materials such as dust, small particles and small blocks. It can be conveyed horizontally, inclined and vertically. During transportation, the scraper chain is completely buried in the material, so it is called a buried scraper conveyor.

Bulk materials have properties such as internal friction and lateral pressure. When conveying horizontally, the material is pushed by the scraper chain in the direction of movement. When the internal friction between the material layers is greater than the external friction between the material and the groove wall, the material will move forward with the scraper chain. When the ratio of the height of the material layer to the width of the machine slot meets certain conditions, the material flow is stable.

When conveying vertically, it mainly relies on the arching characteristics of the material. When the material in the closed machine tank is pushed by the scraper chain in the direction of movement, and is resisted by the continuous feeding of materials from the lower part to prevent the upper material from sliding down, it will generate lateral side pressure, thus increasing the internal friction of the material. When the friction between the materials When the internal friction force is greater than the external friction force between the material and the groove wall and the material's own weight, the material will be transported upward along the scraper chain to form a continuous material flow.

Since the scraper chain vibrates during movement, the supply of some materials will sometimes be destroyed and sometimes formed, which will cause a hysteresis phenomenon for the chain during the transportation process of the material, affecting the transportation capacity.

2. Application scope and selection principles

The buried scraper conveyor is mainly composed of a closed-section trough, a scraper chain, a driving device, a tensioning device and other components. The equipment has a simple structure, small size, good sealing, and is relatively convenient for installation and maintenance; it can feed materials at multiple points and unload materials at multiple points, and the process selection and layout are more flexible; when conveying flying, toxic, high temperature, flammable and explosive materials , can improve working conditions and reduce environmental pollution. Buried scraper conveyors are widely used in chemical industry, building materials, metallurgy, electric power, grain, light industry, transportation and other sectors.

3. The buried scraper conveyor has the following requirements for materials.

1. Bulk density of materials: =0.2-2.5t/m³.

2. Material temperature: The applicable material temperature of the general model is less than 120℃; the temperature of the hot material conveyed material is 100-450℃.

3. Moisture content: The moisture content is related to the particle size and viscosity of the material. Generally, it should be the degree that it can still be loosened after being kneaded into a ball by hand.

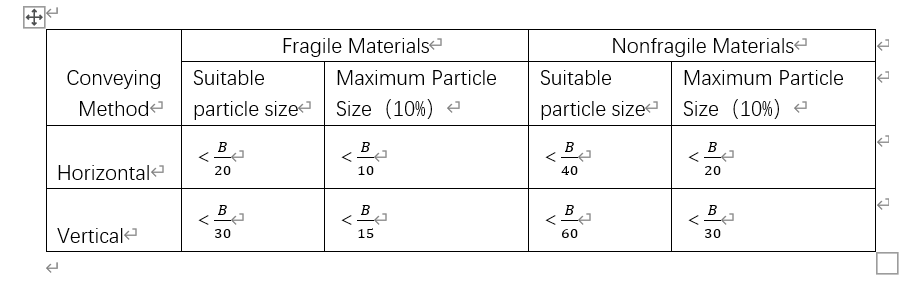

4. Material particle size: see Table 1-1

Generally, the maximum horizontal conveying length is 80-120mm; the vertical conveying height is 20-30m.

For materials with the following properties, buried scraper conveyors are generally not suitable:

(1) Highly suspended materials;

(2) Materials that are too large in size;

(3) Very abrasive materials;

(4) Materials with excessive compressibility;

(5) Materials with high viscosity;

(6) Materials with extremely high fluidity;

(7) Materials that are fragile and do not want to be broken during transportation.

(8) Particularly hard materials;

(9) Highly corrosive materials should not be used without effective anti-corrosion measures.