Brief Introduction & Difference betweenCement Plant & Cement Grinding Station

Part 1. Types of cement:

1.1 Portland cement. Any hydraulic cementing material made of Portland cement clinker, 0-5% limestone or granulated blast furnace slag, and an appropriate amount of gypsum is called Portland cement (commonly known as Portland cement abroad).

Portland cement is divided into two types: those without mixed materials are called Type I Portland cement, and the code is P. I;

When Portland cement clinker is ground, limestone or granulated blast furnace slag mixed with no more than 5% of the cement mass is called Type II Portland cement, code P·II.

1.2 Ordinary Portland cement. A hydraulic cementing material made of Portland cement clinker, 6%-15% mixed materials, and an appropriate amount of gypsum mixed and ground, called ordinary Portland cement, code P. O.

1.3 Portland slag cement. A hydraulic cementitious material made of Portland cement clinker, granulated blast furnace slag, and an appropriate amount of gypsum mixed and ground, code P. S. The mixing amount of granulated blast furnace slag in cement is 20% to 70% by mass percentage.

1.4 Pozzolanic Portland cement. A hydraulic cementitious material made of Portland cement clinker and pozzolanic mixed materials and an appropriate amount of ground gypsum mixed and ground, code P. P. The content of the pozzolanic mixed material in the cement is 20%-50% in terms of mass percentage.

1.5 Fly ash Portland cement. A hydraulic cementitious material made of Portland cement clinker, fly ash, and an appropriate amount of gypsum mixed and ground, codenamed P·F. The content of fly ash in cement is 20%-40% by mass percentage.

Part 2. Brief Introduction of Cement Plant

2.1 Raw materials for cement production:

Raw materials: limestone + other additives (clay, iron ore powder, gypsum, etc.)

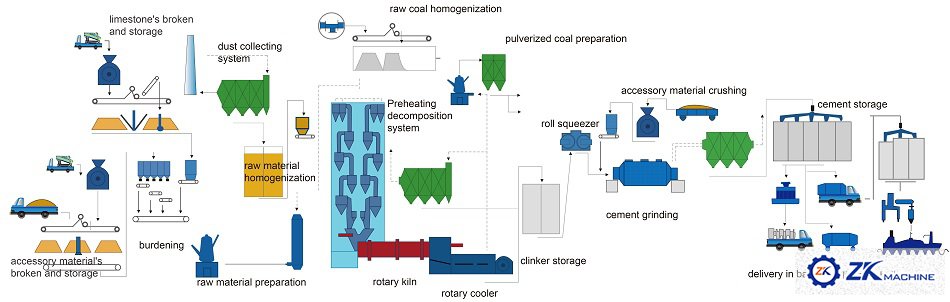

2.2 Five Important Steps of Cement Production Line:

2.2.1 Crushing & prehomogenization: cement crusher crush limestone and other materials and stacker and reclaimer homogenize them.

2.2.2 Raw material preparation: use cement mill to process materials into required sizes for cement clinker production.

2.2.3 Clinker production: In the cyclone preheater system, the raw material powder exchange heat with high-temperature air in the state of suspension. The further rapid decomposition of carbonate in the rotary kiln produce the cement clinker.

2.2.4. Cement grinding: Cement mill grinding cement clinker into finished cement, which is related to quality of cement.

2.2.5 Cement Delivery:Cement delivery can be delivered in bags or bulk.

Part 3. Brief Introduction of Cement Grinding Station

3.1 Raw material for cement grinding station:

Raw material : clinker + other additives (gypsum, etc.)

3.2. Four Important Steps of Clinker Grinding Plant:

3.2.1 Batching: The shipping clinker is discharged into the dock crane and then transported to the clinker warehouse. After unloading at the bottom of the tent warehouse, it is transported to the clinker batching warehouse. Gypsum and slag are transferred from the loader to the crusher for crushing and then hoisted into gypsum and slag storehouse respectively.

3.2.2 Weighing, mixing and feeding: The clinker, gypsum and slag are discharged from the bottom of the respective silo, and then sent to the stable flow weighing silo by the belt conveyor, and the belt conveyor is equipped with an iron remover. The materials are mixed in a steady flow weighing chamber and maintained a stable material level, and then fed into the roller press uniformly and continuously in the form of a column of materials. After being rolled by high pressure, the physical structure is destroyed, forming a cake and lifting it by a hoist .

3.3.3 Grading: The classifier breaks the cake and grades it, and then separates the fine powder less than 6mm from the coarse powder more than 6mm. The coarse powder is returned to the stable flow weighing bin of the cement roller press, and then extricated again, and the fine powder is fed into the cement mill. After the fly ash is measured by the reamer scale, it goes through the chute into the hoist and feeds directly into the cement mill through the chute and the feeding chute.

3.3.4 Grinding: After cement mill grinding, materials enter into the powder separator, the fine powder is sent to the cement silo by the air transmission chute and the elevator, the coarse powder back to the cement mill to continue grinding. One part of the outgoing cement is controlled by the bottom unloader of the fluidized warehouse, and then through the air conveying chute and the elevator, sent to the packaging machine room for delivery, while the other part is sent to the bulk carrier for delivery by the air conveying chute.

Part 4. Difference between cement grinding station and cement plant:

4.1 Procedure: The cement grinding station only has a cement mill and packaging system; while the cement plant includes a full set of production lines such as mining, raw material grinding, clinker making, cement grinding, packaging and sales.

4.2 The nature of the factory: The cement grinding station is a cement product production unit that separates the final product stage in cement production; the cement plant includes the complete cement production process.

4.3 Processing characteristics: During the processing stage of the cement grinding station, the cement clinker is added to the appropriate amount of mixed materials for grinding to produce finished cement; the production of cement plants can generally be divided into three types: raw meal preparation, clinker calcination and cement grinding process.