Types and application of granulator by Henan ZK Corp

Granulators are widely used in chemical, building materials, metallurgy, pharmaceutical, fertilizer, plastic, food and other industries. The granulators produced by our company are generally used in the building materials and metallurgical industries, and mainly include the following types:

1. Disc granulator

Disc granulator are mainly used in fertilizers, building materials, metallurgy and other industries. The particle size is generally Φ3-Φ10mm, which can continuously feed in and discharge materials. At present, the diameter of the largest disc ballizing machine manufactured by our company is 5m, and the output can reach 40-45t/h. There are two types of ball discs: powered scrapers and unpowered scrapers. Generally, it is recommended for customers to use non-powered scrapers to make ball discs less than Φ2.0m, unless the customer has special requirements.

2. Pot granulator

The pot granulator is mainly used in the petroleum proppant industry, and the particle size is generally 30-140 mesh. At present, the maximum diameter of this kind of granulator made by our company is Φ4.2m, and the volume reaches 14m³. This kind of granulator generally has strict requirements on powder. The fineness of powder is generally above 325 mesh. The finer the powder, The higher the yield.

3. Double roller granulator

The double roller granulator is mainly used for construction ceramsite. It belongs to extrusion granulation. The finished product is generally 8-14mm cylindrical. At present, the largest such granulator produced by the company is Φ800×700, with an output of 6-8t/h, simple structure, convenient operation and maintenance, but the roll skin is a vulnerable part, and the general replacement cycle is 6 months.

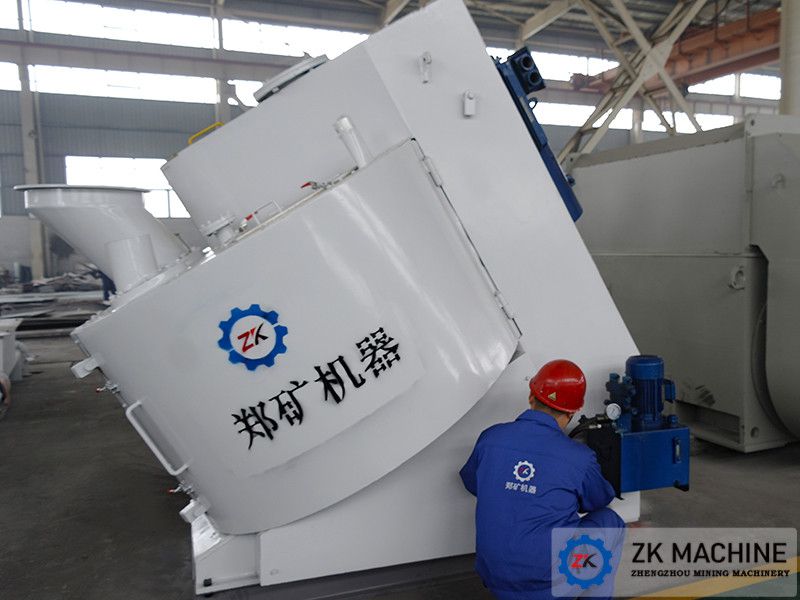

4. High-efficiency granulator

The ZKZL series clean powerful granulator produced by Henan Zhengzhou Mining Machinery Co., Ltd. is developed on the basis of absorbing and borrowing mature foreign technology and combining with the current production status of my country's current petroleum fracturing proppant. It is mainly used in petroleum fracturing support Agent (ceramsite sand) production, also used for granulation of powder, granule and small pieces material such as coal powder, limestone, coal gangue, clay etc.

It is mainly used for the introduction of petroleum proppant into balls. The largest diameter manufactured by the company is Φ1.9m and the volume reaches 1000 liters. Its remarkable feature is that it only takes 8-10 minutes for each pot to granulate.

5. Drum granulator

The drum granulator is consistent with the application industry of the pelletizing disc. At present, the drum granulator manufactured by our company has a maximum size of Φ3.2×8m, which was exported to Brazil. Its structure is similar to that of a single-cylinder cooler and dryer. Compared with the ball-forming plate, its ball-forming smoothness and strength are slightly worse.

6. Briquetter

The briquetter is mainly used in the magnesium industry. It is a dry powder press ball with a moisture content of ≤1%. This type of equipment is generally contracted by our company, and the production capacity is generally 3-10t/h.

The selection of the granulator generally needs to consider the characteristics of the raw materials, the requirements of the finished product, and the relevant process configuration. Regarding the selection and quotation of the granulator, if you have any questions, please feel free to contact us.