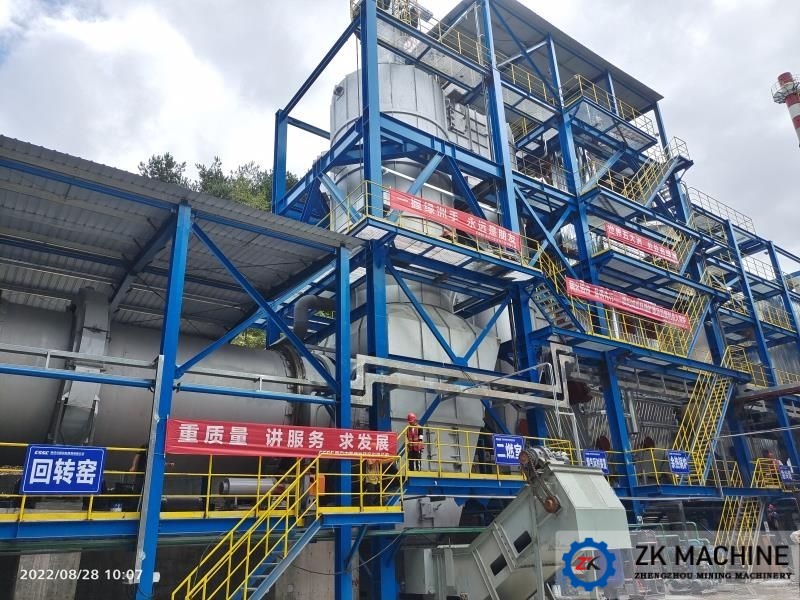

Major equipment:

The inner diameter of the rotary kiln barrel is φ3600mm and the length is 13000mm. Tilt angle 2 degrees. Driven by the transmission device: main motor (frequency conversion), main reducer, and gear ring gear. The rotary kiln is equipped with an auxiliary motor and an auxiliary reducer for maintenance. The kiln head cover, the sealing device between the kiln head and the cylinder body, the sealing device between the kiln tail and the inlet of the cyclone dust collector, and the supporting wheel device, etc., are sealed with fish scales and labyrinth seals.

System Features:

The hazardous waste incineration system is mainly based on the rotary kiln + secondary combustion chamber incineration technology, adopts advanced and mature technology at home and abroad, determines the process route and equipment configuration according to the characteristics of the treated materials provided by the owner, and provides customized whole-process services for the owner to ensure that pollutants emissions meet current standards.

Outstanding advantages:

1. Provide a complete whole industry chain service, with a complete solid waste treatment system solution;

2. Advantages of hazardous waste products: high-temperature incineration to achieve harmlessness, reduction, stabilization, and recycling;

3. Advantages of solid waste products: resource disposal, waste utilization, production of building ceramsite;

4. The heat load of the furnace is large, and the materials are fully incinerated, which is enough to deal with the full incineration of a large amount of hazardous waste.

Application scope:

It is suitable for various tailings, tailings slag, papermaking white mud, carbide slag, aluminum ash, polluted soil, urban medical waste, domestic sludge, municipal sludge, acid sludge, etc.