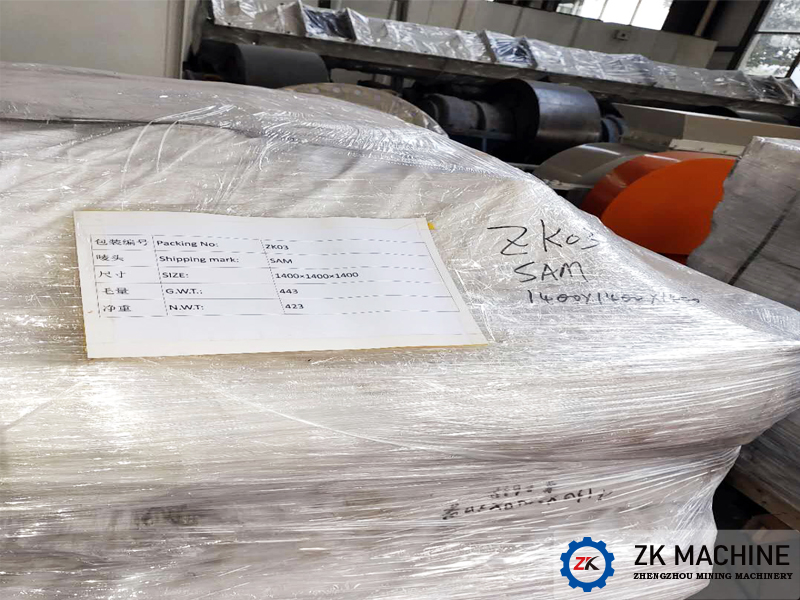

Materials: FMS needled felt filter bag

Model: Φ130×2450mm

Quantity: 1148pcs

Owner: Iran CCPC Company

Material: river sand gold

Contract time: September 305, 2020

Packing time: November 02, 2020

Manufacturing cycle: 35 days

CCPC of Iran purchased our limestone crushing and screening / calcination / cooling / quick lime digestion and powder separation system in the year of 2017.

The production line has been running for three years, and the equipment is in good condition. In September this year, the customer purchased 1148 filter bags for the high temperature bag filter of the lime rotary kiln.

The specific technical parameters are as follows:

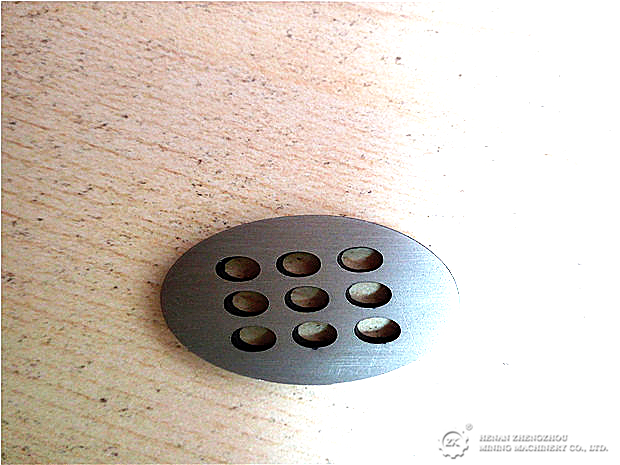

FMS needled felt filter bag

Materials: Antistatic coating, Polyester needle felt

Surface fibrous layer: 100% polyester fiber

Base material:

Polyester filament yarn electric conduction base cloth

Weight(g/m2): 550

Thickness (mm): 1.8

Density (g/cm3): 0.30

Permeation volume (L/ dm2.min): 30~40

(200Pa) Breaking strength: (N/20x5cm)

Vertical: ≥1100

Horizontal: ≥1300

Breaking elongation(%):

Vertical: ≤30

Horizontal: ≤40

Operating temperature (℃)

Normal: 130

Instant: 150

Hot-shrinkage rate % (150℃, specification 400x400mm)

Vertical: ≤1

Horizontal: ≤1

Anti-static:

Surface resistance ≤1010

Volume resistance ≤109

Surface treatment: Heat setting, singeing, press polish, PTFE coating