Project Overview:

Shenmu Moyuan Dingtai Magnesium Industry Co., Ltd. was established on July 23, 2008, and its registered place is located in Qiandian Industrial Concentration Zone, Yongxing Office, Shenmu City, Yulin City, Shaanxi Province. The business scope includes sales of metal products; common non-ferrous metal smelting; non-ferrous metal alloy manufacturing; non-ferrous metal alloy sales; non-ferrous metal casting; ferroalloy smelting; brick and tile manufacturing; high-performance non-ferrous metal and alloy materials sales; high-quality special steel materials sales; coal and product sales; coal-based activated carbon and other coal processing.

Project Description:

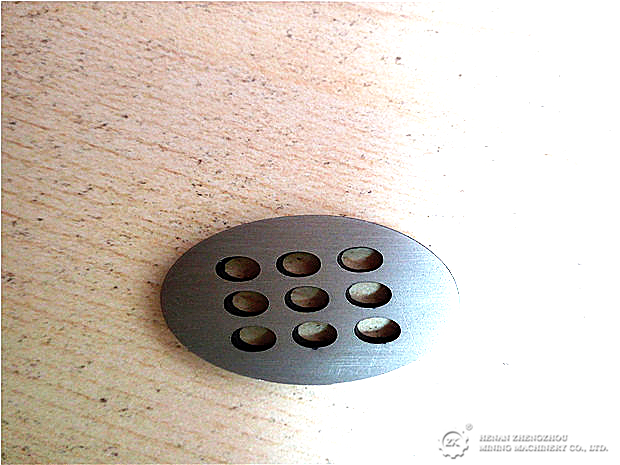

The customer purchased a set of our company’s 3m diameter calcined white rotary kiln production system in 2008. The system has been in normal production and operation until it was discovered that the cylinder at the end of the kiln was deformed some time ago. Due to the high temperature of the whole body, the material used is 310S, which can operate in high temperature environment for a long time. Deformation after 12 years of operation is normal equipment wear. The customer contacted us for a quotation at the first time. We explained the latest technology to the customer. By changing the structure, the service life of the whole body was greatly extended. Although there are many small local sales factories disrupting the market through inferior quality and low prices, the customer is unmoved and quickly signed a spare parts procurement contract with our company.